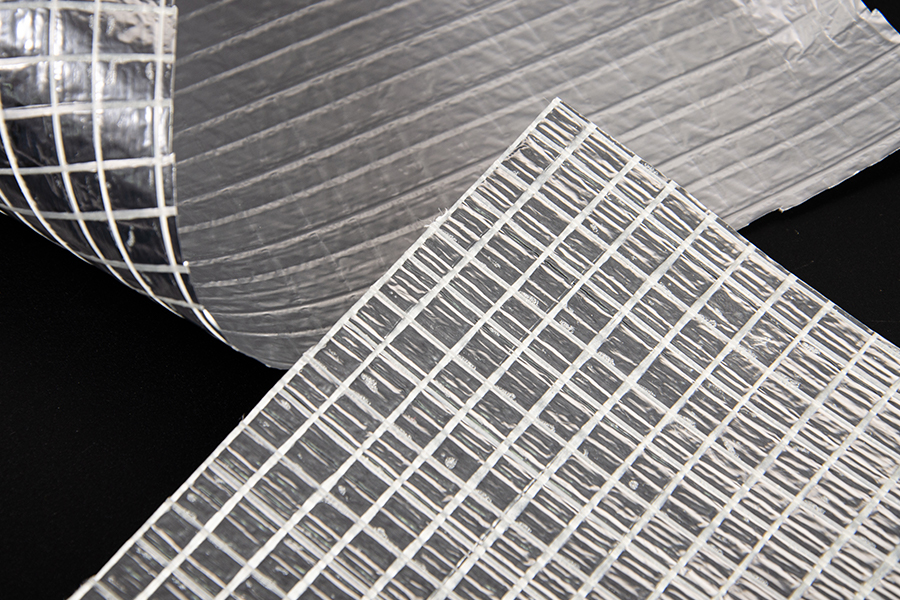

| Item | Test Standards | Data | Unit |

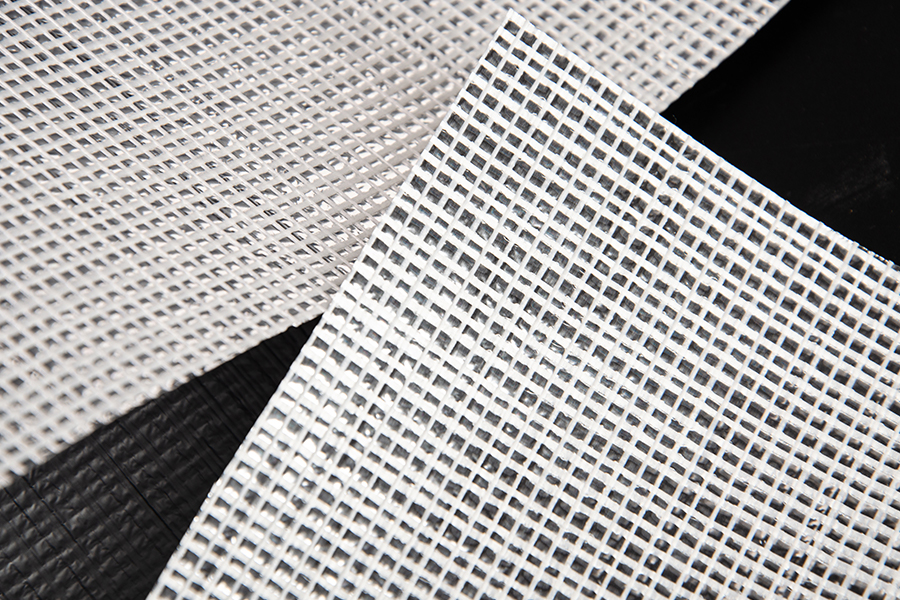

| Size of Scrim | / | 3*3 | /cm |

| GSM | EN 29073-1 | 129 | g/m² |

| Thickness | EN 29073-2 | 0.42 | mm |

| Breaking Strength | EN 29073-3 | 1180 | N/5cm |

| Tensile Strain | EN 29073-3 | 24 | % |

| Strength @ 5% Elongation | EN 29073-3 | 156 | N/5cm |

| Strength @ 15% Elongation | EN 29073-3 | 357 | N/5cm |

| Resistant to Tear | DIN 53363 | 390 | N |

English

English 中文简体

中文简体 Español

Español Deutsch

Deutsch